Meet Truman, first born among tardigrade babies and affectionately named by my granddaughter Lydia. He’s one of more than two dozen (in this first batch!) 8-inch foam figures sculpted in clay and cast in a silicone mold.

When I observe my granddaughter and other children playing with the color brood, I have a feeling these cuties will become the runaway stars of Tardigrades In Space!

Sure, they’ll get into mischief, but sometimes they’ll also save the day as adult “Tardigrups” pilot them through teachable microverse adventures aboard the I.S.S. Eukaryote.

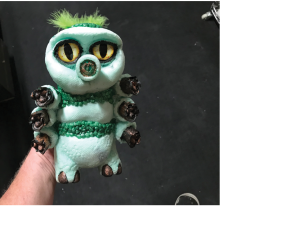

Each “Tardibabe” is uniquely cast in a single batch of tinted polyurethane foam and decorated with irridescent paints, puppy-dog eyes and wispy feathers. Every casting has random imperfections, and it seemed right to leave their “scars” and “birth marks” in hommage to every living creature’s unique and individual representation on Earth.

In keeping with the show’s special sensitivity to “the least of these”, one little guy came out so rough that I made him a prosthetic foot as talking points for promoting empathy and compassion in young viewers. Indeed, those most challenged psycho-socially often teach caregivers the greatest humility and compassion.

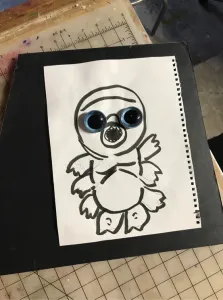

[1] I started with a simple sketch to scale with the large “puppy-dog” eyes I purchased online. The eyes are transparent, so I place a colored disc of paper or craft foam behind it to color the iris.

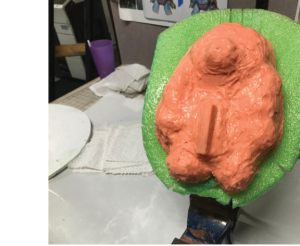

[2] The basic body shape was carved from a block of green florist’s foam and covered with pliable aluminum screening. Like stucco (houses in the Southwestern U.S. often use this concrete-paste instead of wood siding), modeling clay requires a textured substrate for proper adhesion to the base form. I’ve learned to make my base form smaller than the finished size to allow for the thickness of the “MonsterClay” I build up for texture and details.

[3] I went through several attempts and sculpting the baby’s snout.

[4] The FlexFoamIT-III by Smooth-On is “self-skinning” and can capture intricate details from the silicone mold walls. So, for the babies, I put a lot of tiny textures into the clay sculpture.

For scale, here I am holding one of the two bottom “feet” before adhering them to the body by slightly melting both surfaces with a heat gun; the wax-based clay bonds and cools in a few seconds.

[5] After sculpting an individual “hand,” I poured a silicone mold and cast additional hands using liquid MonsterClay melted in the microwave. I could have cast rigid copies using Smooth-On 65D plastic resin, but at the time I was out of that product. It was a great discovery nonetheless, as liquid MonsterClay begins solidifying almost immediately, especially if I’ve chillled the silicone mold in the freezer before pouring the liquid clay.

[6] Here are detailed images of skin textures, front and back. On the front view you can see the “arms” with hollowed-out pits; each of the six clay “hands” will be inserted, as well as the final “snout” (not shown) before brushing on the silicone mold. Unlike the large adult Tardigrades (which are cast as a head, body with hollow voids, and six individual hands), each puppet baby will be cast as a single foam rubber piece.

[8] When I first placed this photo below, I assumed it was the finished clay sculpture standing next to it’s silicone mold. But then I realized it was actually a foam-rubber casting I had tinted chocolate brown! It captured mold details so well, I thought it was the original clay sculpture.

[9] After coating the master clay sculpture with a thick layer of Silicone (a one-to-one mixture of two polymer liquids), I built up a two-part plaster shell with the same infused gauze used by human doctors to set a cast on a broken arm or leg. These rigid “mother molds” are necessary because silicone shells are pliable (“rubbery”), and the expanding foam would produce a deformed casting lacking a proper skin.

To create a two-part Mother Shell, I build a temporary “coffer dam” with expanded foam SWIMMING KICK BOARD purchased at my local Dollar Store. Plaster gauze is applided to this half, then the coffer dam removed and the other half of the silicone mold it covered with plaster gauze. At this point the two halves are separated by a layer of aluminum foil. To keep this Mother Mold thin and light-weight, I layered in aluminum screen mesh for rigidity. This is the same aluminum screen used to wrap the florist’s foam before applying MonsterClay.

[10] Here is the silicone mold (orange) next to plaster halves of the “Mother Mold” (white shells, left). The disc beneath the orange mold is a circular sheet of expanded PVC screwed to a ball-bearing Lazy-Susan unit; this allows me to spin the mounted object for easier application of silicone, plaster, etc.

[11] Here is a wider view of the “chocolate” foam puppet standing next to the silicone mold (orange) and plaster Mother Shell (white). Behind are the blue and white gallon jugs of Smooth-On FlexFoamIt-III, which are mixed at a one-to-one ratio and tinted with batch-by-batch colorant pigments. In the very back are several colored TardiBaby castings awaiting finishing with irridescent paints, ostrich feathers and acrylic puppy-dog-eyes.

[12] Here are the 25 foam-rubber castings made from the initial Silicone Mold. Number 25 experienced some serior deformations as the mold succumbed to the chemical ravages of “pulling” cast polyeurethane puppets from the rubber mold. In other words, the orange silicone mold “failed,” and the resulting foam cast stuck to the mold walls in the same way that muffin or cupcake leaves behind a gritty outer later on the baking tin or paper inserts.

A “rough blue baby” can be seen on the far left, second row from the front. He is the 25th and final puppet casting before the catastrophic mold failure [00]. He was deformed by how much of his skin had stuck to the failing silicone mold and missing most of his left foot. I was going to discard him, but recognized his potential as an role model for children with physical challenges and source of empathy for typically-abled children in the viewing audience.

[13] After two dozen foam castings, the silicone mold “failed,” meaning the expanding foam stuck to the mold walls, which I learned was due to the leaching of the oils that give silicone its nonstick properties. In fact, all silicone molds will eventually fail after numerous castings depending on the chemical properties of the resins, plastics or foams being used for casting.

Fortunately, I had just enough two-part Silicone in stock that I was able to make a replacement silicone front half using the original MosterClay sculpture (the back half of the silicone mold was still in good shape). To avoid this mold-failure dilemma from the start, it is advised that one of the first castings should be made with a rigid resin to create a “library cast” that can be stored for making many future silicone molds. I used Smooth-On SmoothCast 65D—the same two-part plastic resin I used to pour over 100 miniature Tardigrade figurines about this time last year.

[14] Because the resin becomes extremely hot during the chemical curing process, and that volume of expensive resin would come out quite heavy, I did what is called a “Slip-Cast” or “Roto-Cast,” by pouring several small batches of liquid resin into the hollow silicone mold and swishing it around until each layer cured into a tough outer shell.

Then I mixed and poured a small amount of rigid SmoothOn FoamIt 5 polyeurythane foam, which is brittle and bubbly like the green Florist’s foam. This inner “Back Fill” method produces a lightweight casting with a rigid, full-detail skin that I will now tuck away safely for when I need to craft a replacement silicone mold.

[15] Here, the weathered outer “mother shell” resembles a giant clam covered with tropical corals.

[16] TARDI-CHOW: Each tinted-foam casting produced small amounts of overflow. I pour these onto waxed paper to build up “micro-biomes”…basically abstract wall art interpreted as the organelles, microtubules, vescicles and DNA contained in the cytoplasm of the plant cells real Tardigrades schlurp out of plant cells using their tooth probiscuses.

[17] A TAR IS BORN: each TardiBaby starts as a tinted foam rubber character (insert). Layers of flexible fabric paints add lustre and luminescence to the base skin color. Glass eyes replace molded foam sockets, acrylic paints adorn hands and body segments, and brightly dyed ostrich and turkey feathers complete the hairline.

[18] BLUE BABY: This archaic term for infants who struggled to get sufficient oxygen during birth is å pro pos for the deformed 25th casting mentioned in caption [12]. Here is a picture of his rough foot beside a “bronze” prosthesis I made from the same silicone puppet mold by slip-casting a thin wall of SmoothCast 65D. INSET: the prosthetic easily slips on and off and stays put while the tyke thumps around the nursery at play.

[19] And here’s another flamboyant TardiBaby. I’ve been calling them puppets, but they’re more like cuddly stuffed animals. However, they will still be used in video production with limited body movements and carefully framed close-ups.

The limitless variety of color and error will provide ample character assignments (both flaws and strengths!) to communicate the truth-and-consequence moral compass of…

Tardigrades

innnnn

Spaaaaaaace!

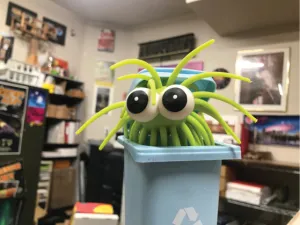

[20] INSPIRED BY SESAME STREET: From items purchased at a Dollar Store, I “puppetized” a blue plastic “recycling bin” with a pop-up friendly virus named “Pico.” He’s a silicone squishy-ball with bulging eyes that I affixed to a slender steel rod and control through a hole in the bottom of the small bin [INSET]. I added a salvaged spring to help the lid snap shut after this viral “Oscar the Grouch” pops back down into his blue bin that’s “Bigger on the inside than it is on the outside!”

Hmmm—it didn’t occur to me until writing the above entry…a recycling bin is an apt home for a virus (versus Oscar’s galvanized garbage can), because viruses reproduce by pulling the chemical building blocks from the host cells they infect…recycling, or perhaps “up-cycling” materials.